Car window lift are generally divided into two categories: electric and manual. Manual glass lifters have all the components of the electric type except for the motor, and in the manual type, the power of the passenger’s hand is used instead of electric energy. In the act group section, we introduce and work on each part of the Car window lift system.

The components of the car window lift system

Are generally divided into two categories: electric and manual Manual glass lifters have all the components of the electric type except for the motor, and in the manual type, the power of the passenger’s hand is used instead of electric energy In general, the electric lifting glass set consists of the following components (Figure 1).

pic

Figure 1: The position of installing the glass on the lifting glass and how to assemble it on the car door.

- Carrier: The main task is to transfer the glass, it holds the glass and moves it up and down. The way to connect the glass to the carrier may be by screwing, connecting with rivet pin, two conflicting points or by other methods.

- Energy production source: which is provided in electric elevators with a DC motor and in manual elevators by turning the handle by hand.

- Energy production source: which is provided in electric elevators with a DC motor and in manual elevators by turning the handle by hand.

- Rail: Usually, in order to guide and control the glass in the right direction for going up and down according to the design of the curved form of the door, there are rails (channel or channels) that control the direction of the glass movement.

In other words, by moving on the channel, the carrier travels a certain path according to the curvature of the door and glass. - Power transmission factors from the motor or hand to the glass: intermediate factors are used to transfer power from the electric motor or hand to the glass. These factors can be in the form of cables or metal arms.

Types of mechanisms

Common mechanisms used in current cars can be divided into 7 categories.

1. L-shaped

This mechanism can be used for cars where the glass course is small, as well as for rear doors with smaller dimensions or places where the transmission force is not high.

figure 2

L-shaped mechanism of this lifting glass consists of the following components:

Engine and gearbox in electric type or shell and manual gearbox in manual type:

- Torque transmission cables

- Rail

- Carrier

- Spiral plastic part 1: By connecting to the spiral wheel in the electric type and by connecting to the handle in the manual type, it transfers the torque to the cables wrapped on it.

- Solar shock absorbers: These shock absorbers are used to reduce the amount of noise caused by the collision of cables with other components.

- Springs: The function of springs is to compensate for the change in the length of power transmission cables and covers.

2. Delta 2

As seen in Figure 3, the components of this mechanism consist of a gearbox assembly, a spiral plastic piece, a rail, and a carrier similar to the L-shaped mechanism and have the same functions.

The only difference is the way the cable is placed on the rail. In this type of mechanism, in some cases it is possible to solve the problem of stability of the glass in the path of movement by using a part called the guide plate, which is usually plastic and is placed inside the sealing strips.

Figure 3

3. Binary Mechanism

Two metal rails, two glass carriers, shell and gearbox set, wire and cable set and metal body covering for the engine, springs and shock absorbers.

The task of each of the above components is the same as the description of the tasks given in the previous sections.

With the difference that the metal body supporting the motor has been added to this set, which is used to keep the motor or the shell set stable.

This mechanism is used in cars where the ratio of the length to the width of the glass is high to prevent the glass from turning (rotational movement of the glass).

These types of glass lifters need a lot of space to create proper movement and are used for doors with large dimensions.

Figure 4

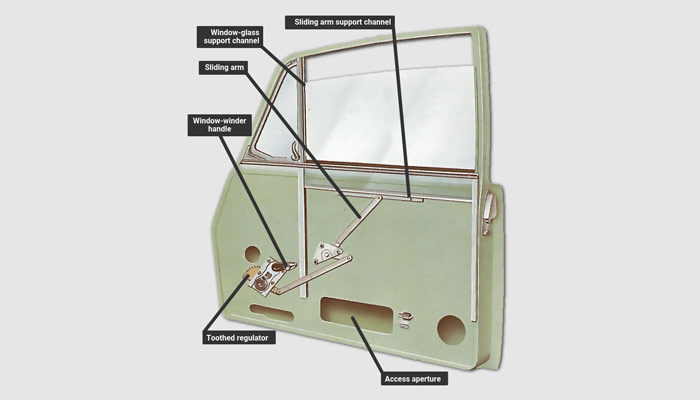

4. Scissors mechanism Figure 4

Arms: This mechanism consists of three arms. The main arm, which is larger, is usually connected to the motor or the shell assembly by means of a gear wheel and the other side of it is placed by a pulley in the groove of the rail connected to the glass and moved in the transverse direction, which is the main factor of power transmission.

- To the glass The other arm is pinned to the main arm in the center on one side, and on the other hand, it is located inside the rail connected to the door and has transverse movement, this arm actually works like a support and causes the glass to rise.

The last arm is connected to the middle of the main arm on one side and is located on the rail connected to the glass on the other side. Its task is to raise and lower the glass.

This arm and the second arm act like a single arm, but are made in two pieces for ease of assembly and installation. - Rollers inside the rail: because the movement of the arms is both in the vertical direction and in the horizontal direction, rails must be used to provide movement in this direction by the movement of the rollers inside them.

On the other hand, these rollers in the channel reduce the frictional force with their rolling motion.

Figure 5

Other components of the mechanism are:

- Main body

- Rooster crown gear

- Engine and gearbox in electric type and shell assembly in manual type

- Rails. scissor mechanism 5 It is the most common type of lift glass used in new cars. In general, relatively difficult design and construction, high reliability and high weight and construction cost are the characteristics of this mechanism.

5. Arm mechanism 6

- Main arm

- Lower arm

- Rooster crown gear

- The engine and gearbox or the shell assembly, the way it works and the description of its functions are similar to the scissor mechanism, with the difference that in this mechanism (arm-shaped mechanism) there is only one arm that performs a task similar to the main arm in the scissor mechanism.

This mechanism is mostly used to raise and lower the rear windows.

Figure 6

6. Composite lifting glass 7

As seen in Figure 7, this type of lifting glass is composed of few components. This reduces assembly and manufacturing errors, thus requiring less testing.

Considering the reduction of friction and the increase of system efficiency in this type, a smaller drive motor with less power is needed, which will cause less noise.

By optimizing the entire mechanism and increasing its capabilities, it is possible to use anti-seize standard 8 has been created.

In addition, apart from using the exact standard, this system has good flexibility and can be used in different conditions and doors.

Figure 7

7. Anti pinch window

Lifters of new cars have the ability that when the automatic window lifter is active, if there is an obstacle blocking the way of the glass movement, the window will automatically stop and then go back five centimeters. This is done when the glass goes up.

Currently, cars equipped with automatic lift system also benefit from the above safety system. Also, the new systems have the ability to raise all electric windows automatically if the doors are closed by central locking.

This is done in the following two ways:

- Pressing the door lock button on the remote control twice

- Holding down the door lock button on the remote control for at least two seconds, the amount of self-sufficiency of this car window lift system, which has a value share of 0.9% compared to the whole car, is about 75% in the country, and its mechanism is completely internalized, and in terms of the engine The gearbox of this system has also been planned to be built inside it.

0 Comments