Today, due to the many advances that have been made in the field of new technologies in the Automotive industry in Iran , due to the better performance of parts, we see an increase in the safety of car occupants.

One of these important parts in the car is the electric power steering (EPS), which plays a significant role in this field, which we discuss in detail in this section of Act Group .

Electric power steering (EPS) system has been used since the early 90s for assembly on cars in reputable automobile companies. This advanced steering system had very positive capabilities and performance in the field of vehicle and passenger safety, so that it could replace the HPS hydraulic steering system in cars.

Also, the electric power steering (EPS) in the car has reduced the failure rate of the car steering systems, more comfort, better driving experience and even more car safety.

Most of the cars in the market these days benefit from the electric power steering or EPS, and in the future we will see more improvements of this system.

What is electric or electric power steering?

Steering assist systems are an integral part of today’s cars. Without these systems, it will be very difficult to steer cars and not only cause early driver fatigue, but also reduce driving safety.

In addition, the stiffness of the steering wheel without the presence of auxiliary systems causes the driver to suffer a lot when moving the car at low speed, such as parking.

Steering assist systems have two main types, the first and older type is hydraulic and the new generation is electric.

The hydraulic system has been used in various cars for decades and many advantages can be mentioned for it along with a few small disadvantages, but in newer cars we see the replacement of the hydraulic steering system with an electric assist system.

Components of electric power steering system (EPS)

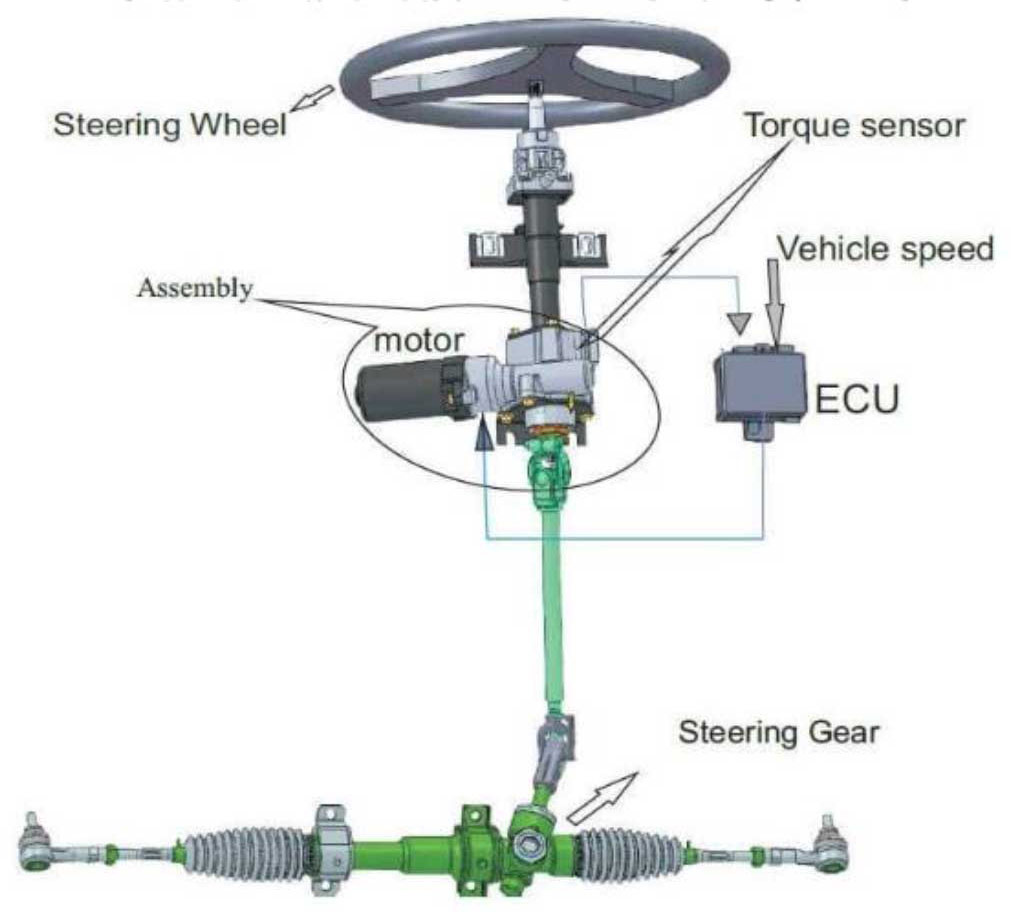

The most important components of the electric steering system include sensors, brushless electric motor and electronic control unit (ECU).

The sensors in this system measure the speed of the wheels, the rotation angle of the wheels and the amount of torque applied by the steering wheel and inform the ECU.

Then the electric motor applies the necessary angle and force to the wheels based on the command received from the ECU.

How does the electric power steering (EPS) work?

The function of the electric steering system is that first the sensor senses the torque coming from the steering wheel and sends it as a signal or signals to the ECU electronic control unit.

In addition to this signal, the microcontroller of the electric steering unit also receives a signal from the vehicle speed.

Then it processes these two signals and applies the necessary instructions to the electric motor to help influence the mechanical components of the steering system.

Therefore, the ECU instructions to the electric motor are a function of the output of the torque sensor and the speed of the vehicle.

This means that in order to make the car more safe, speed is effective in EPS performance , and the highest performance at low speeds and the lowest steering performance at high car speeds can be seen.

Considering that the main and most important component of an electric steering system is its electric motor, in this section it is necessary to provide brief information about the type of electric motor used.

Brushless electric motor

As you know, electric motors are used to convert electrical energy into mechanical energy. Different types of engines are used in different industries. One of the types of electric motors is the brushless motor, which is another name for the direct current (DC) motor without a brush.

It is interesting to know that this engine was invented in the middle of the 19th century. In Brush type electric motors, a part called a broom is used to transfer current to the rotor, and with the rotation of the rotor, the poles are moved and the motor starts moving.

During this time, the life of the motor is reduced, and this is where the role of brushless motors becomes more colorful.

Brushless motors are actually synchronous electric motors that move with the help of electric energy. Such motors have magnets in their structure that receive power from direct electric current and cause the rotor to rotate inside the stator.

In these motors, the winding part is fixed and magnets are placed inside it, which can receive the required power and energy by means of direct electric current and cause the rotor to rotate inside the device. For this reason, there is no need for a brush to transfer the voltage to the coils.

Brushless motor

Due to the fact that these motors do not have a brush and have a special structure, they have many advantages. The absence of a brush minimizes friction during operation, reduces heat generation, produces less noise, weighs less and is smaller than conventional engines, does not produce sparks, and ultimately increases productivity and longevity.

Another important advantage of Brushless motor is its high efficiency. A conventional direct current motor can only reach maximum torque at certain points in its cycle, but a brushless motor works continuously at maximum torque.

The controllability of this engine is very high and the use of feedback mechanism to achieve the desired torque and speed makes it easy to control.

pic

As mentioned above, the brushless motor has high controllability and with a small change in the control program, a big jump can be made in the speed of the system.

This has caused these engines to be widely used in home appliances, automobiles (especially electric steering systems), aerospace, medicine, automatic industrial equipment and machinery, and quadcopters.

Also, due to the fact that this type of motor is very ideal and suitable for power control, we will see more applications of it in different products in the future.

Types of electric steering based on installation on the car

The electric steering system can be installed on the mechanical components of the car in three different modes.

1. Installation on the pinion (P-EPS)

In this method, the sensors, the brushless electric motor and the ECU part are placed as a set in a chamber and installed on the pinion. Currently, Dena, Peugeot 207 and Tara cars are equipped with this type of steering wheel.

This mode is suitable for semi-heavy cars and the driver of these types of cars can drive the car in the most comfortable mode.

2- Installation on the steering column (C-EPS)

In this method, sensors, brushless electric motor and ECU part are installed as a set in a chamber and installed on the steering column.

Therefore, the assisted function of the EPS command is applied to the steering column. Currently, this generation of electric steering wheels is installed and used on most production cars around the world. Haima S5 and S7 cars are now equipped with this type of steering wheel made by JTEC.

This method is used in small cars, especially in city cars, where steering comfort is an important factor in heavy traffic and car parking. The steering column is engaged with the DC electric motor by a helical gear.

3- Installation on shoulder gear (R-EPS)

In this method, all three parts of the electric steering wheel, i.e. the sensors, the brushless electric motor and the ECU part, are installed separately on the steering box.

In such a way that the DC motor and ECU are placed separately on the shoulder gear (Rack) and the sensors are also placed on the pinion. Because there is no torque on the shoulder gear that the sensors can sense.

This mode is suitable for heavy vehicles where a lot of force must be applied to the shoulder gear. Therefore, the assisted power is directly inputted from the DC motor to the shoulder gear.

EPS electric steering and HPS hydraulic steering

HPS hydraulic steering added new components to cars and increased the energy and fuel consumption of most cars.

In fact, these steering wheels did not operate completely independently and freely, and due to being connected to the car’s engine, they still consume a lot of energy even when they are not moving during driving.

This made the researchers of the automotive industry think of making a new system for steering wheels, and as a result, electric steering wheels or EPS were invented.

Instead of using the power of the car’s engine, which increases fuel consumption, the electric steering wheel is equipped with a small and independent engine and does not increase energy consumption like the hydraulic steering wheel.

15 advantages of electric steering over hydraulic steering

In general, the only difference between the electric steering system and the hydraulic system is that it leads to the elimination of many additional components and is very effective in reducing the fuel consumption of cars, and it only works when the steering wheel has rotation or torque.

Among the most important advantages of this type of command, the following can be mentioned:

- Removal of hydraulic pump and its waste

- Removal of control valves and connection pipes

- Removal of belts between hydraulic pump and car engine

- Removal of hydraulic jack and hydraulic oil

- Light weight compared to hydraulic system

- Fewer changes in the mechanical part of the steering wheel when designing the electric steering wheel Compared to hydraulics,

- The failure of electric power steering assistance when torque is not input (in other words, when the steering wheel is turned, the electric part comes into action)

- Electric power steering is in Safe Fail mode . (If the electric part fails for some reason, the mechanical part of the steering wheel can continue to work.)

- The amount of energy and fuel consumed in the electric steering wheel is about one-sixth of the energy consumed in the hydraulic steering wheel. In other words, 85% of the energy consumption of electric steering is saved compared to hydraulic.

- Reduction in volume and size compared to hydraulic

- Being independent from the car engine

- Significantly reducing assembly time

- Significantly increasing the effective life of parts compared to steering. Hydraulic

- High safety capability in critical conditions

- The possibility of using one type of electric steering wheel in several different cars

Driving quality with electric steering system

The driving quality with the electric steering system is much different than the hydraulic steering type and it brings a very interesting and safe experience for the driver. However, one of the main criticisms of the electric power steering system is related to drivers who are interested in sports cars.

Such drivers do not enjoy the controllability of these types of steering wheels and believe that the pleasure of driving with electric steering wheels has been lost.

Of course, automakers have not sat idle and manufacturers such as Mazda, Porsche and BMW have been able to bring the feeling of driving EPS steering wheels as close as possible to hydraulic steering wheels.

Conclusion

Introduce you to the operation, application and benefits of the electric steering system and brushless motors. In fact, the sensitive and quick reaction of the electric steering system to the car’s speed has increased the safety of cars and also increased the stability of the car at high speeds.

In fact, when you are driving at high speed on the highway, surely a small mistake and a slight turn of the steering wheel can lead to an unfortunate incident.

But the presence of an electric steering system can increase the stability of the car at high speeds by making it harder to turn the steering wheel.

Comparing this system with the previous steering systems, it can be clearly seen that the electric steering system can work much smarter due to its effective connection with the car’s ECU and can involve different car modes and speed changes in the amount of steering wheel rotation as well as the car’s controllability.

This work will greatly help to increase the proper driving experience and increase car safety to the extent that the installation of electric steering wheel can be considered as one of the competitive advantages of cars.

0 Comments