The environmental laws regarding the production of cars with less fuel consumption and the production of fuel with a better standard grade are also getting stricter every year. Likewise, car manufacturers are trying to play an important role in reducing air pollution by introducing cleaner models, in addition to implementing these strict rules. In the meantime, various mechanisms and technologies have been developed to reduce emissions, one of which is Exhaust Gas Recirculation System (EGR), which is briefly reviewed in this article from Act Group.

Air pollution is one of the biggest problems of developing countries, and the role of cars and fuel used in them cannot be ignored in this regard.

In this regard, attention has been paid to reducing the engine emissions of cars with gasoline and diesel (petroleum gas) fuel.

The environmental laws regarding the production of cars with less fuel consumption and the production of fuel with a better standard grade are also getting stricter every year.

Likewise, car manufacturers are trying to play an important role in reducing air pollution by introducing cleaner models, in addition to implementing these strict rules.

In the meantime, various mechanisms and technologies have been created to reduce emissions, one of which is EGR, which is briefly reviewed in this article.

The role of nitrogen oxides in air pollution

Exhaust gases include several pollutants, among which nitrogen oxides, which are generally represented by the abbreviation NOx, cause the greatest environmental risk.

Nitrogen oxides play the greatest influence in the formation of smoke that causes respiratory diseases in big cities and acid rain, and for this reason, the most importance in pollution laws has been focused on these compounds.

The pollutant compounds of diesel engine exhaust include carbon monoxide, sulfur dioxide, soot particles, unburned hydrocarbons and nitrogen oxides.

Although the exhaust gas recirculation system is used to control engine impact and to control nitrogen oxides and control greenhouse gas production, this system also affects the performance of hydrocarbon gas emissions.

In recent years, car manufacturers have tested various ways to reduce the level of pollution resulting from combustion in cars. One of the main solutions for diesel engines is the use of exhaust gas recirculation system.

This system has the task of reducing the level of nitrogen oxides in the exhaust of car engines and especially diesel engines as much as possible.

How nitrogen oxides are formed

Of emphasis on its reduction, is nitrogen oxides or NOx. By knowing the source and how this pollutant is formed, it can be removed from the source and prevent its formation. Nitrogen oxides, as their name suggests, are the result of combining nitrogen with oxygen.

These two gases do not combine with each other in a natural state, but when both gases are in close proximity to each other at a very high temperature, they are activated and combined.

The main source of nitrogen gas production in the car is the high temperature in the combustion chamber of the engine.

The maximum temperature in diesel engines at the time of peak combustion and in the center of the flame varies from 1800 to 2100 degrees Celsius and in gasoline engines from 850 to 1400 degrees Celsius, this temperature will create an active bond between nitrogen and oxygen molecules.

Oxygen and nitrogen gases are among the components of air in the atmosphere and enter the combustion chamber with air.

On the other hand, it is not possible to prevent these gases from entering the combustion chamber because oxygen is one of the components of combustion and power generation in the car engine, without which it is not possible to generate power in the car engine.

The oxygen required by the engine is sucked into the engine from the ambient air, but due to the lack of pure oxygen in the environment and its mixing with nitrogen, nitrogen will enter the car engine in a much larger proportion.

Because the ambient air contains 78% nitrogen and 21% oxygen, and in this way, when the air enters the car engine during the suction phase, a large amount of these two gases enter the engine, and it is practically impossible to prevent nitrogen from entering the engine, but as It was mentioned that these two substances do not want to combine with each other in their natural state and normal temperature, and the small amount of natural nitrogen oxides in the atmosphere around us is also caused by the extreme heat of lightning that sometimes occurs.

Considering the formation conditions of nitrogen oxides and the impossibility of preventing nitrogen entering the engine, it seems that the only option to control and prevent the formation of this dangerous compound is to control the compound conditions by reducing the temperature of the combustion chamber.

Of course, reducing the ignition temperature will result in costs because this temperature control, due to the prevention of the maximum release of fuel energy, has caused a drop in the output power in the car engine, and if it is necessary to maintain the stability of the output power, more fuel must be used to compensate for it.

Cycle is used. Depending on the type of EGR system used, the amount of additional fuel to obtain equal power from two similar engines with EGR system and without this system varies between 2 and 10%.

How to control the combustion temperature

Now that we understand the source and how NOx is formed as one of the main engine pollutants and know that this pollutant is produced at a very high combustion temperature, it seems that the most ideal action for this purpose is to reduce the engine combustion temperature, but in addition It is not so easy to increase the fuel consumption, because the combustion happens instantaneously, and with solutions such as cooling the cylinder body, etc., it is not possible to help reduce the combustion temperature.

One of the solutions to reduce the combustion temperature is to make the air intake of the engine heterogeneous, this heterogeneity can be created by returning a part of the exhaust gases to the engine.

The main idea in this system is to use the exhaust gases and return a part of it to the combustion chamber along with the intake air, so that the combustion temperature can be reduced and NOx production will be limited.

As part of the exhaust gases enter the air intake of the engine and thus the combustion chamber, the amount of oxygen in the combustion chamber becomes more limited and with this the combustion temperature of the fuel and air mixture decreases.

Such an action is done without reducing the output power of the car engine, because the oxygen that is reduced here from the chamber is excess oxygen, and for this reason, the engine can still receive the appropriate amount of oxygen that it needs to continue its work.

On the other hand, the entry of engine exhaust gases into the combustion chamber slows down the speed of reactions in the cylinder chamber, which, due to the delay in the release of fuel energy, contributes to the reduction of nitrogen oxides production.

Limiting the use of fuel energy in the working cycle of the engine will cause a slight drop in the full use of fuel energy, but considering the value of the leap created in reducing the amount of pollutants, the power loss can be ignored. The name of this system comes from here.

The basis of EGR work is based on the return of part of the exhaust gases of the engine to the combustion chamber.

The return rate of exhaust gases depends on the engine speed, the amount of oxygen remaining in the exhaust smoke, the ambient temperature, the engine temperature, the altitude of the environment, etc.

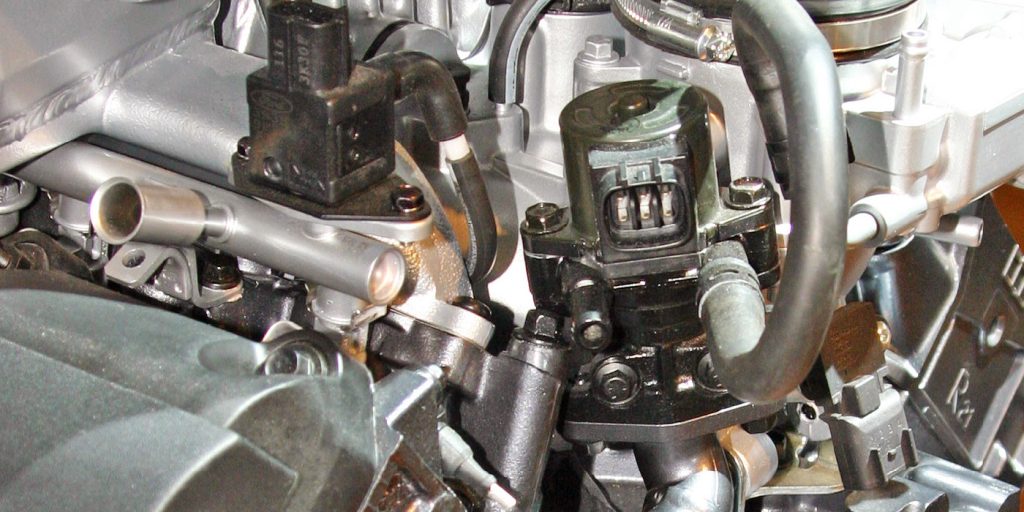

For this purpose, in simple terms, a secondary circuit is taken from the engine exhaust outlet, which can separate part of the exhaust gases from the main path and re-introduce it to the engine air manifold path after cooling.

As mentioned, EGR should be able to reduce the combustion temperature, but due to the high temperature of the gases leaving the engine -in some engines this temperature is more than 700 degrees Celsius- if the engine exhaust gas is returned directly to the combustion chamber, practically not only The temperature will not decrease, but it will increase the temperature of the combustion chamber.

For this reason, a cooler is installed in the gas flow path to cool the exhaust gases before re-entering the manifold, and thus the exhaust gases are at a lower temperature -the ideal temperature is 80 to 110 degrees Celsius- Enter the engine.

Cooling of the exhaust gases in light engines is done by ambient air, and in heavy engines, a separate circuit in the cooling system is used for this purpose, and the engine cooling system is actually responsible for reducing the temperature of the return gases.

In the path of this cooler, there is a special valve that can deliver air directly to the intake manifold without entering the cooler when necessary, for example, when starting the car, while a valve is also installed in the path that controls the flow of exhaust gases in the path. is in charge and is known as the EGR valve.

In this way, part of the exhaust gases enter the engine’s intake air path after being cooled and compressed and can reduce NOx production by reducing the combustion temperature.

Side benefits of the EGR system

The general structure of the EGR, in addition to the great advantage of reducing NOx pollution, also helps to improve engine performance.

The optimal efficiency of engines takes place at the ideal temperature of the engine, this temperature is in the range of 75-73 for gasoline engines and 81-79 degrees Celsius for diesel engines.

Internal combustion engines suffer from incomplete combustion at the time of starting and when the engine temperature has not yet reached the ideal operating temperature, which is more evident in the case of diesel engines, because the basis of the operation of these engines is not based on the spark of a candle, but on the basis of ignition caused by The temperature of the combustion chamber is high.

At moments when the intake air, fuel and engine block are cold, the amount of additives in the exhaust gases is high, and this problem can be seen in heavy models with black smoke coming out of the exhaust.

On the other hand, if there is a catalyst in the path of the exhaust smoke of the engine, this catalyst cannot perform its task well even when it is cold, and it needs to increase the temperature of the engine and the temperature of the exhaust gases to be activated.

Therefore, a cold engine, especially if it is diesel, is prone to high emissions, and heating the engine faster will be effective in reducing this emission as much as possible.

In engines with an exhaust gas recirculation system, at the start of the engine, according to the engine temperature and exhaust gas temperature by special sensors designed for this purpose, the EGR management system enters the engine heating phase.

With the direct return of the relatively hot exhaust gases to the engine’s intake air, it causes the engine’s intake air to become hotter, and as a result, it is possible for the engine to quickly reach the ideal temperature and to shorten the pollutant production cycle at the beginning of the car’s engine start-up.

Monitoring the exhaust gas recirculation system

The exhaust gas recirculation system is designed to detect improper or excessive exhaust gas recirculation flow and the performance of its components.

When the EGR valve is open, the ECM confirms that the exhaust gas flow is stopped, and when the EGR valve is closed, the ECM confirms that the exhaust gas flow has stopped.

Sensors also monitor EGR system open, half-open, and functioning.

There are three methods to detect the performance of this system:

- EGR

- Temperature detection method EGR MAP

- Detection method EGR valve position/temperature detection method Detection methods can be used according to the type of sensors used (Figures 5 and 6).

EGR:

Temperature detection method This method is used for the control system to cut off the recirculation flow of exhaust gases. An EGR temperature sensor is installed in the EGR passage.

During normal flow, the EGR sensor temperature will rise at least 35°C (95°F) above ambient temperature.

When the flow is insufficient:

When the EGR valve is open, the ECM compares the EGR temperature with the intake air temperature. If the temperature rises more than the specified temperature from the ambient temperature, the ECM assumes that there is a problem with the system and this information is stored in the ECM.

If the problem repeats a second time, improper EGR flow will be detected and 4 MIL will light up.

When the flow is excessive:

When the EGR valve is closed, the ECM measures the EGR temperature. If the EGR is open, the temperature will be higher than expected.

If the problem repeats a second time, improper EGR flow is detected and the MIL will light up.

EGR MAP

Detection method This method is used for the control system of cutting off the recirculation flow of exhaust gases in engines equipped with MAP sensor.

The MAP sensor is used to detect EGR flow, therefore, this sensor does not include the EGR temperature sensor:

- When the EGR valve opens and the manifold pressure increases: The MAP sensor generally detects the increase in manifold pressure.

- When the flow is not enough: With the EGR open, if the MAP signal is not higher than the calculated value, it will indicate the presence of restrictions in the exhaust EGR chamber.

- When the flow is excessive: With the EGR closed, if the MAP signal is higher than the calculated value, it will indicate that the EGR valve is open.

At idle, if the MAP is higher than expected, it indicates that the ignition is incomplete.

EGR Valve Position/Temperature Detection Method This method

Works on the EGR constant vacuum system by using a temperature sensor for improper EGR flow and an EGR valve position sensor for excessive EGR flow.

- When the flow is excessive: The ECM detects excessive flow using an EGR valve height position sensor.

- When the EGR valve is closed and the sensor signal is greater than the specification stored in the ECM: The ECM assumes that the valve is not fully closed.

- When the problem repeats a second time: Improper EGR flow is detected and the MIL will light up.

0 Comments