Which country produces the most batteries for electric vehicles?

The growth in the use of electric vehicles led to an increase in the production of lithium-ion car batteries in 2020, which has increased by about 33% compared to 2019.

China is still the leading country in battery production, accounting for more than 70% of global production capacity.

However, Europe has not been left behind as the growth in battery demand has exceeded European production capacity and has intensified investment in this field. According to a Bloomberg report, Europe’s share of global battery production will reach 31% by 2030. This figure was only 7% in 2020.

What is the global market for electric vehicle batteries?

According to the International Energy Agency (IEA) , the number of electric cars in the world will increase more than 14 times by 2030 and reach 145 million units. Meanwhile, power companies are building massive fleets of batteries to store electricity.

Lithium-ion batteries are expected to continue to dominate the battery industry, especially in the transportation industry. But the CATL battery research company has produced a sodium ion battery that does not contain nickel, lithium or cobalt.

Battery optimization process for electric vehicles

transformation in Battery features, due to the high demand in consumer electronics, will create several benefits for the electric vehicle business.

Future developments in this field will be mainly in three areas:

- changes in battery chemistry

- energy density ratio

- size

Future vision of batteries for electric vehicles

The battery is practically the most expensive part of an electric car. However, with research and measures in progress, while improving performance in the above three areas, its price will also decrease.

According to predictions, this situation will change in 2023 in such a way that the price of an electric vehicle will be equal to the price of an internal combustion vehicle.

By 2023, the cost of lithium-ion batteries is expected to reach about $100 per kilowatt-hour a price at which electric cars are cheaper to build than gasoline powered cars.

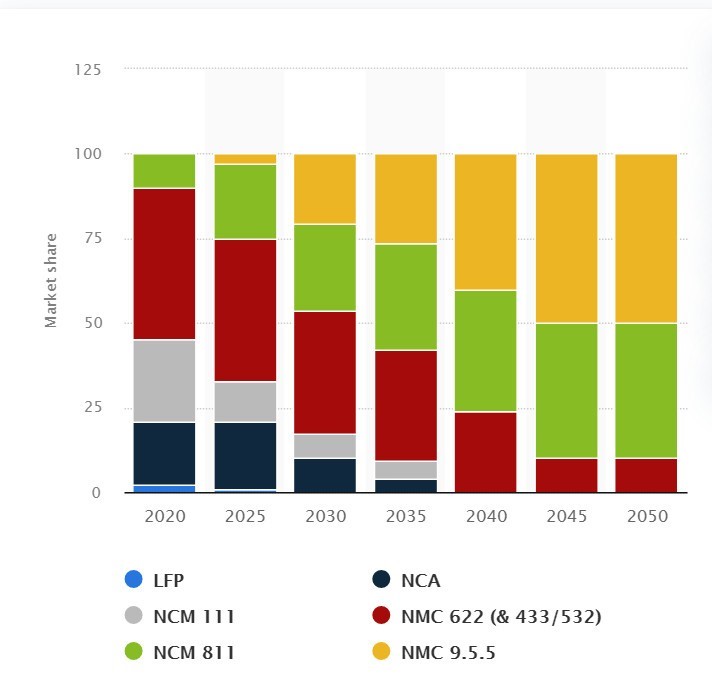

The global electric vehicle battery market is expected to move away from the use of LFP, NCA and NCM 111 cathodes in the next two decades.

By 2040, nickel/cobalt/manganese (NCM) lithium-ion batteries are expected to account for about 40% of the global automotive battery market Take electricity.

References

- https://www.virta.global/global-electric-vehicle-market

- https://www.canalys.com/newsroom/global-electric-vehicle-sales-up-160-in-h1-2021-despite-supply-constraints

- http://aspaev.ir/1400/06/08

- https://www.reuters.com/technology/new-ev-battery-designs-unlikely-dampen-metals-demand-miners-say-2021-08-06/

- https://www.visualcapitalist.com/electric-vehicle-battery-prices-fall/

- https://www.statista.com/statistics/1248519/distribution-of-different-electric-vehicle-batteries-on-the-global-market/

0 Comments