The automotive industry in North America is experiencing significant changes for the first time since General Motors declared bankruptcy in 2009. Despite the increase in car prices and the growth of fuel prices in this region, the car market is still strong and growing. Here you will learn about the importance of steel in the automotive industry and the types of steel grades used in this industry. Stay with the act group.

Economic indicators indicate that despite new tariffs and an increase of more than 4 dollars per gallon in the US, the amount of inventory 1 of many automakers is high.

However, in a world where the use of self-driving and electric cars and the use of internet taxi services such as Uber enter the operational phase from theory, it has become very important to change the methods of car production and the culture of using it in the world.

According to the studies, renting a car is cheaper than owning or buying a car. According to the Economist, the use of taxi services in rich countries is $2.50 per mile.

While this figure is $20.1 for private cars, Uber and Lyft companies have made the use of taxi services economical and reduced by almost 60%.

According to the UBS investment bank. the trends of automation, competition and electrification of the car will reduce the costs of traveling the car by 70% per mile and will reduce this figure to 70 cents.

The emergence of the third generation of Steel in the automotive industry, in the near future, apart from economic and cultural issues, the existence of a world with fewer cars does not mean ignoring the issue of reducing fuel consumption and safety in cars.

This actually indicates the growing role of advanced high-strength steels in future vehicles. According to the CEO of the Swedish steel company SSAB, car styling in order to consume less fuel along with improving car safety are both important.

For this reason, automakers are increasingly asking their suppliers to use a wide range of resources in this changing environment.

According to the announcement of this steel company, which has a history of 12 years of activity in the American market, it is now focusing on high-strength advanced steels 2 Especially the Docol brand is placed.

The first generation of high-strength steels dates back to the 1980s. On the other hand, the effort to increase the strength and flexibility of 3, during the last ten years, actually created the second generation of AHSS steels.

On the other hand, using very hard forms of the crystal structure of steel known as martensite 4, QP technology 5 and manganese steels 6 In fact, it forms the third and emerging generation.

According to SSAB company, the third generation of advanced steel has improved flexibility and application.

The meaning of flexibility is that this generation of steel can produce more complex geometric shapes in cold form 7 compared to the first generation.

This category of steels has the necessary flexibility in terms of ingredients. In addition, the third generation of steel plays a decisive role in the field of structural parts of the car body 8 will have.

Because they will have a more resistant weight ratio and a lower cost compared to more expensive methods such as the use of aluminum profiles or hot-stamped boron steels.

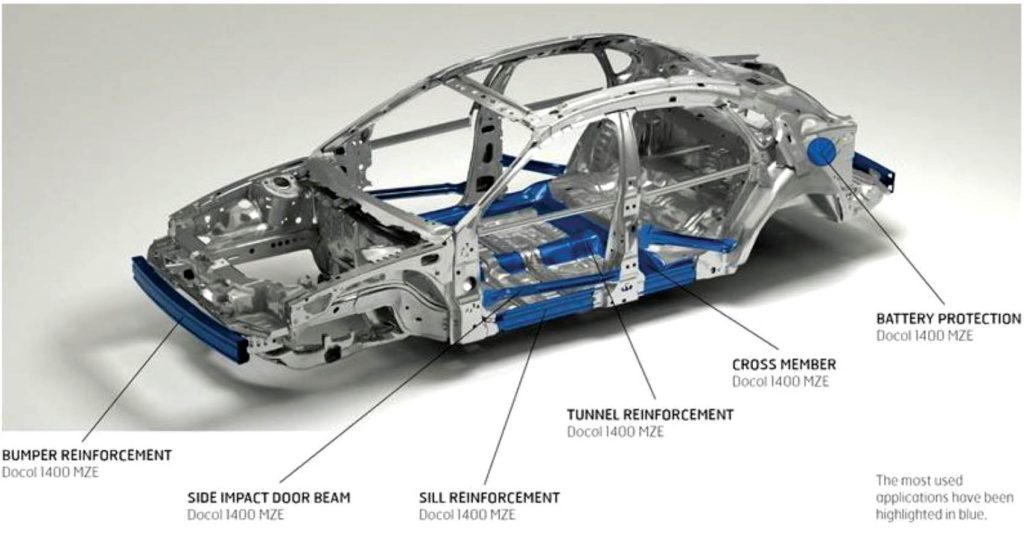

figure 2

AHSS steel on electric vehicles

The introduction of electric vehicles into the market actually means getting closer to a cleaner world, and in this context, the use of AHSS steel will play a significant role.

However, one of the main challenges in the field of using steel in the automotive industry is actually improving and expanding the battery range of electric vehicles.

The basic method to improve this field is to reduce the frictional resistance 9 Is. The main factor influencing the frictional resistance is the weight of the car. Therefore, it is important to use light and resistant steel in this field.

By using AHSS steel with cold capability from car manufacturers, it is possible to reduce the weight of complex parts without using expensive processes and energy on hot forming 10 will be provided.

This is possible in the design of most parts such as bumper, chassis, seat frame and other parts.

0 Comments