Many countries of the world are planning to mass produce all-electric cars with the aim of dealing with air pollution, reducing the amount of pollutants and greenhouse gases and protecting the environment. In this section of Act Group, you will get the latest The progress of electric vehicle battery technology.

The Chinese government also plans to ban the manufacture and production of gasoline and diesel cars that pollute the environment and cause air pollution and then the disease of many citizens.

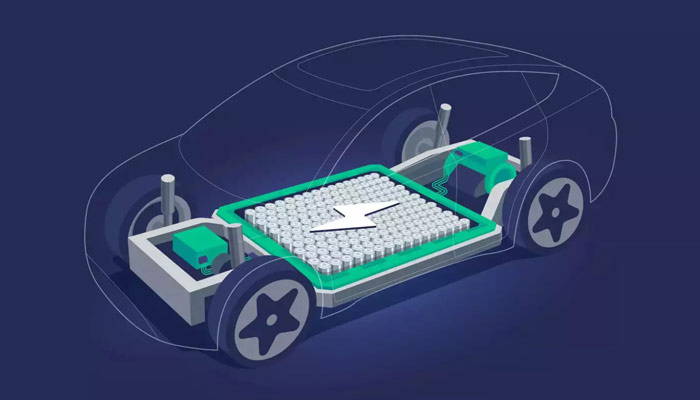

Introducing the Samsung electric car battery

Samsung’s battery production department (SDI) unveiled its latest battery model designed for electric cars, which is said to have a range of 645 kilometers.

According to the mashable website, Samsung has announced that it plans to produce batteries for electric vehicles that can travel long distances. In this way, Samsung competes with the American company Tesla, which has the largest factory for the production of electric cars.

Many countries in the world are planning to mass produce all-electric cars with the aim of dealing with air pollution, reducing the amount of pollutants and greenhouse gases and protecting the environment.

It is rarely seen that companies active in the field of lithium-ion battery production have a prominent presence at an auto show, but the Korean technology company Samsung has decided to shine at the Frankfurt Auto Show 2017 by unveiling and introducing the latest generation of electric vehicle batteries.

Samsung’s battery production department (SDI), which supplies batteries for cars of major companies such as Audi and BMW, has now unveiled a new generation of electric car batteries. These batteries have more capacity and it is said that they can cover a distance of 645 kilometers with each charge.

The advantage of these new batteries is that despite the increase in dimensions (5 mm in height and 3 mm in diameter), compared to the previous batteries, they have about 50% more capacity.

By using new batteries that have more capacity, fewer of them are needed to provide energy, and as a result, smaller battery sets, with less weight and more interior space for passengers are obtained.

The team of Samsung engineers and experts believe that this battery can cover a distance between 600 and 700 kilometers with each charge.

Samsung has decided to compete closely with its American rival, Tesla, by making a difference of 200 miles between the power of Tesla car batteries and its own cars. Of course, Samsung has been very successful so far.

Tesla Motors has been producing batteries for electric vehicles for many years and has a lot of experience in this field, but now Samsung has unveiled batteries that can beat its American rival.

Of course, Samsung’s multi-functional battery technology has not yet been tested with real cars and on the road.

The managers of Samsung Battery Production Division (SDI) have noted that the price of such batteries is very high.

In this case, we can only expect them to be used in luxury and expensive electric cars in the world, but placing 10 to 12 battery packs with the ability to travel about 300 km per charge will be suitable for mid-range electric cars as well.

The ever-increasing increase in electric cars and the popularity of more use of these clean cars has caused automobile companies around the world to face a tight competition and unveil each of their plans to design and produce better cars with more navigation power.

The British government is going to ban the production and sale of all gasoline and diesel cars in this country by 2040 in order to deal with the problem of air pollution and use environmentally friendly cars.

After England, other countries and cities such as France, Madrid, Mexico City and Athens also plan to stop the production and sale of gasoline and diesel cars.

In this regard, the Chinese government is also planning to ban the production of gasoline and diesel cars that pollute the environment and cause air pollution and then the disease of many citizens, but the government officials of this country have not yet determined the exact time.

According to published reports, China wants to allocate at least one fifth of car sales in this country to the market of these cars by 2025.

The Indian government also plans to oblige the country’s car manufacturers to electrify all the cars produced in the country by 2030.

In addition to the unveiling of the new generation of batteries for electric ovens, Samsung managers also announced the huge investments made in this field and the completion of the construction of the newest battery factory in Hungary.

Toyota's cooperation with Panasonic to produce batteries for electric cars

Japan’s Toyota Automobile Company plans to produce batteries for electric cars in cooperation with Panasonic in order to expand and improve the technology of clean cars.

Since many countries in the world intend to mass produce all-electric cars with the aim of combating air pollution and reducing the amount of emissions of pollutants and greenhouse gases and protecting the environment, the car manufacturing giants in the world are determined to mass produce these clean cars. They have made a dogma and unveiled their plans for this purpose.

The production of electric car batteries with smaller size and higher charging capacity can be considered a winning card for each of the automotive and technology giants.

In line with its policies and goals, Japan’s Toyota Automobile Company is moving forward in line with its policies and goals, which were supposed to make up half of its sales of clean electric cars in the world by 2030, and for this purpose, it is cooperating with the technology giant, Panasonic.

Panasonic, which is famous for the production of lithium-ion batteries for Toyota’s all-electric or hybrid cars, has signed a contract for the continuation and development of this cooperation with Toyota.

During this cooperation agreement, which was concluded in order to develop and improve production batteries, it is supposed to produce ultra-advanced batteries for all-electric and electric cars in order to make Toyota’s clean and electric cars look different from other electric cars in the market.

Since Toyota plans to increase its production line of electric cars by the beginning of 2020, the need of this car manufacturer for batteries has also increased.

In this way, Toyota intends to meet its need for more and better batteries by expanding its cooperation with Panasonic.

Akio Toyota _President of Toyota Motor Corporation_ stated during a joint press conference: “The automotive industry must think about the new generation of electric vehicle batteries in order to achieve its goals.”

He further added: In order to achieve our goals by 2030, we must increase the speed of current battery production and development, and that is why we have requested companies such as Panasonic and some other famous companies in the battery industry We helped to reach the required quantity and the best possible quality of our used batteries.

Toyota has announced that the annual sales goal of this automobile company until 2030 is 4.5 million cars for hybrid cars and 1 million cars for all-electric cars.

To achieve this goal, in September of this year, Toyota entered into negotiations with its Japanese counterpart, Mazda, and parts supplier Denso, and signed a cooperation agreement with them.

This cooperation was done in order to develop and improve the new generation of clean cars and reduce research, development and production costs.

Many countries such as England, Spain, France, Norway, India and China have announced that they intend to sell and produce polluting cars in the next decade or two in order to prevent air pollution and reduce the amount of pollutants released into the atmosphere and also to protect the environment. Ban and stop gasoline and diesel.

Volkswagen plans to launch its own battery factory

Volkswagen plans to launch its own battery factory, which is as big as Tesla’s battery factory. This issue can be guessed from the multi-billion euro investment of Volkswagen. The German magazine Die Welt writes about this:

10 billion euros is enough for this project, and this amount can take the Volkswagen Group from the production of engines and gearboxes to the production of batteries for electric cars.

Despite the presence of car manufacturers such as Audi, Porsche, Skoda, ect., the Volkswagen company must do its best to be able to sell 100,000 batteries annually.

With the construction of this battery factory, Volkswagen no longer needs Panasonic, LG and Samsung companies and can produce its own car batteries independently.

Volkswagen CEO Matthias Müller and his colleagues are now planning strategies that can increase the sales of electric cars to one million vehicles in the next 10 years.

The aim of these new projects is actually to compensate for the “Dieselgate” cheating in car emissions testing.

The purpose of Volkswagen’s focus on electric cars and batteries of these cars is actually a kind of restart and compensation for the negative image that this company left behind recently.

The main question that has occupied everyone’s mind is whether Volkswagen really knows how to make electric car batteries and if it knows, can it adjust the price of these cars with its competitors? Because other companies have done this many times and failed.

The decrease in the price of batteries has a direct relationship with the increase in the sale of electric cars.

The US Department of Energy announced that the decrease in the price of batteries for electric cars has a direct effect on the increase in sales of electric cars.

In 2009, the DoE announced that the cost of lithium-ion batteries was $ 1,000 per kWh. At that time, the sales of electric cars were almost too low.

In addition, there were very limited models in the market. In 2011, companies began to mass produce electric cars, and as a result, the price reached $ 600 per kWh.

Since then, the price of batteries has dropped more rapidly. From 2009 to 2014, the price of batteries dropped by nearly 71%.

The sale of electric cars reached 300,000 in the same period. Tesla reports that the price of lithium-ion batteries is $.

260 per kilowatt-hour, and in some cases $ 200 , and promises that this price will soon come down.

With the increase in the production of battery and automobile manufacturing companies, as well as the construction of automobile super-companies, we will again see a decrease in prices in the coming years.

Daimler, invests 500 million euros to build a battery factory in Germany

Daimler invests 500 million euros to build a battery factory in Germany. This factory is going to produce lithium-ion batteries for Mercedes-Benz electric and dual-use vehicles and other famous companies.

Li-Tec, which is a part of the Daimler company, stopped battery production in December 2015, and most of the 280 employees of this department were transferred to the Deutsche Accumotive factory, which is also a part of the Daimler company. This factory produces its batteries based on LG Chem batteries.

Daimler company is expanding its activities in the field of electric vehicles and has spent 500 million euros to build a battery factory, which will mean expanding the production of Daimler’s lithium-ion batteries. In the first step, this company has purchased 20 hectares of surrounding land to build this new factory.

Unveiling the details of Chevrolet Bolt battery and engine

in cooperation with LG Chem Company, General Motors Company was able to offer this new electric car with long range, high performance and reasonable price.

This company claims that no electric car similar to this car has been made yet. 60 kWh battery, 200 miles range with each charge and incredible price of $ 37,500 excluding government subsidies are some of the unique features of this electric car.

Except for the unknown plan of the new generation electric car of the Nissan company, which is supposed to come to the market in 2017, the Chevrolet Bolt electric car is the only option available for an electric car with a long and cheap range.

The Chevrolet Bolt battery has three times more energy compared to the Spark electric car battery, but its weight is only twice the weight of the Spark battery.

The features of this battery are as follows:

- 60 kW of energy for a distance of 200 miles

- Battery weight 436 kg

- Power output 160 kW

- 288 350 V

- Lithium-ion

- Battery, 8-year warranty or 100,000 miles

- Fast charging capability (at least 50 kW)

New battery technologies for electric vehicles

While lithium-ion batteries will remain the battery used in most electric vehicles for at least the next ten years, alternative battery technologies (such as lithium-sulfur batteries and solid-state batteries) will grow significantly by 2030.

A report with the title of the new generation of car batteries, how will lithium sulfur batteries and solid state batteries take over the electric car market after 2020?

It predicts that the technology of alternative batteries will reach a value of more than 10 billion by 2030.

Cosmin Laszlo, senior analyst at Luxury Research magazine, says that companies with a large market share should invest in next-generation batteries in addition to continuing to develop existing lithium-ion batteries if they want to maintain their position in the electric vehicle market for years to come.

The summary of this report is as follows:

New generation batteries will grow a lot until 2030, and it is predicted that the sales of lithium-sulfur batteries will reach from 6 billion dollars in 2030 to 29 billion dollars in 2035.

And solid state batteries will reach 42 billion dollars from 3 billion dollars in the same 5-year period.

Solid state batteries will be successful in the electronics market. It is predicted that these batteries will earn 12 billion dollars from the electronic market by 2035, which is about 39% of the market share.

While our prediction is that lithium-sulfur batteries will not have a share in this market due to the problem of energy density and will leave the market in favor of advanced lithium-ion batteries.

0 Comments